Contact Us

(888) 595-0219

Liberty Plaza 165 Broadway Lower Manhattan, 7th Floor, NY, 10006, USA

Jewelry Box

Custom Jewelry Box Printing Service

Custom Jewelry Box Printing Service

A good jewelry box not only can protect the jewelry, also can represent its brand identity and effectually on promoting the brand. As a printing and packaging manufacturer, Prime Printings offers a range of custom jewelry box printing options to suit your specific needs. From material selection to printing methods and finish options, we provide a comprehensive service to ensure your printed jewelry box stands out.

- ☑ Competitive price

- ☑ A wide range of customized options

- ☑ Professional quality printing

- ☑ Truly customer-centric customer service

- ☑ Fast delivery

- ☑ Worldwide shipping

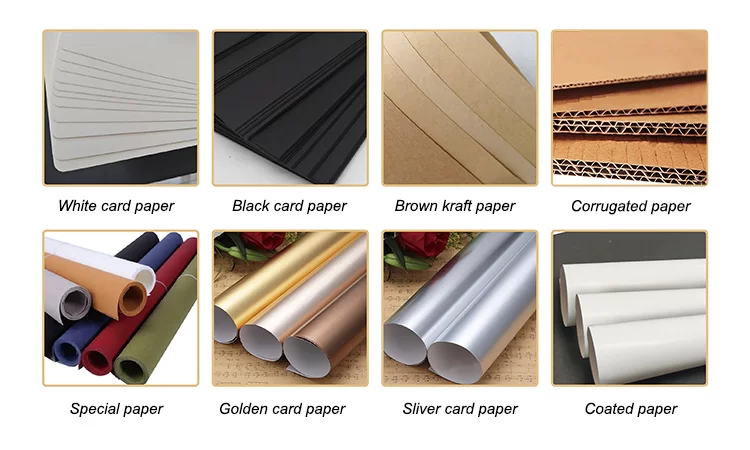

Material Options

At Prime Printings, we provide a wide range of material options for you to choose from.

Coated Paper

Coated paper is a popular choice for custom jewelry boxes due to its smooth and glossy finish. It provides an excellent surface for vibrant color reproduction, making it ideal for showcasing intricate designs and branding elements. Additionally, coated paper offers good structural integrity, ensuring that the jewelry box maintains its shape and form during handling and storage.

C1S Paper

C1S (Coated One Side) paper is another versatile option for custom jewelry box printing. Its coated surface on one side allows for high-quality printing, while the uncoated side usually unprinted. This material is suitable for both elaborate designs and minimalist aesthetics, making it a popular choice for various jewelry brands.

Kraft Paper

For a more natural and rustic aesthetic, kraft paper is a popular choice for custom printed jewelry box. The earthy tones and textured finish of kraft paper provide a unique and eco-friendly option for jewelry box, appealing to customers who value sustainability and craftsmanship.

Special Paper

In addition to the standard paper options, Prime Printings also offers a range of special paper options for printing jewelry box. From textured papers to metallic finishes, these special papers can add a luxurious and distinctive touch to your jewelry box.

Printing Methods

The printing method employed for custom jewelry box production is a critical aspect that directly impacts the visual appeal, color accuracy, and overall quality of the final packaging. At Prime Printings, we provides a range of advanced printing techniques to ensure that each jewelry box meets the highest standards of precision and excellence

CMYK offset printing

CMYK offset printing

CMYK offset printing is a traditional and widely used printing method for custom jewelry box wholesale. It offers a full range of colors and high-quality printing. That makes it perfect for intricate designs and detailed artwork on custom jewelry boxes. The versatility of CMYK offset printing ensures that your printed jewelry box captures the essence of your brand and the beauty of your jewelry items.

Pantone color printing

Pantone color printing

For precise color matching and consistency, Pantone color printing is an ideal choice for custom jewelry box packaging. Whether you have specific brand colors or a unique color scheme for your jewelry packaging. Pantone color printing ensures that your jewelry box accurately reflects your desired color palette, enhancing brand recognition and visual impact.

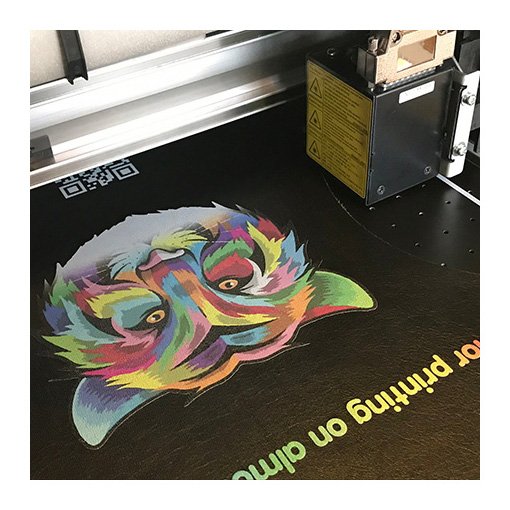

UV printing

UV printing

UV printing offers a high-gloss and durable finish for custom jewelry box printing. The UV printing process involves curing the ink with UV light, resulting in vibrant colors, sharp details, and a glossy surface that enhances the visual appeal of your custom printed jewelry box. This printing method is particularly effective for creating eye-catching designs and intricate patterns on jewelry packaging.

Screen printing

Screen printing

Screen printing is a versatile printing method that can create bold and opaque designs on custom jewelry boxes. With the ability to print on various materials, including paper and cardboard. Screen printing allows for unique and tactile finishes on custom jewelry box packaging, adding depth and texture to your jewelry presentation.

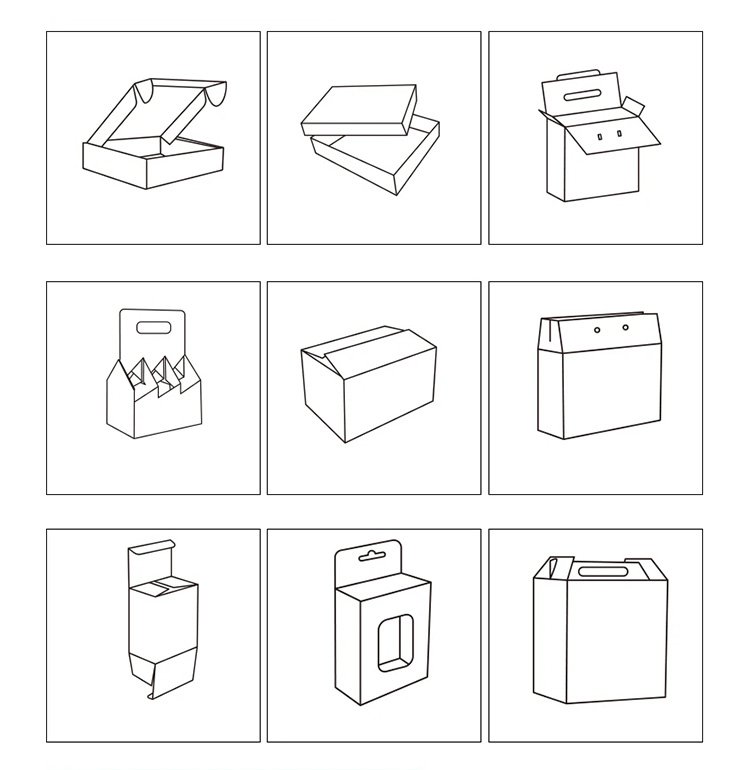

Box Styles and Lining Options

Prime Printings understands that different products require different box shapes and interior linings. We offer a wide range of options to cater to your specific needs. Whether you need a standard rectangular box, a round box, or a custom shape, we have the expertise to bring your vision to life. Our skilled team can create intricate die-cut designs, ensuring that your paper boxes are not only functional but also visually appealing.

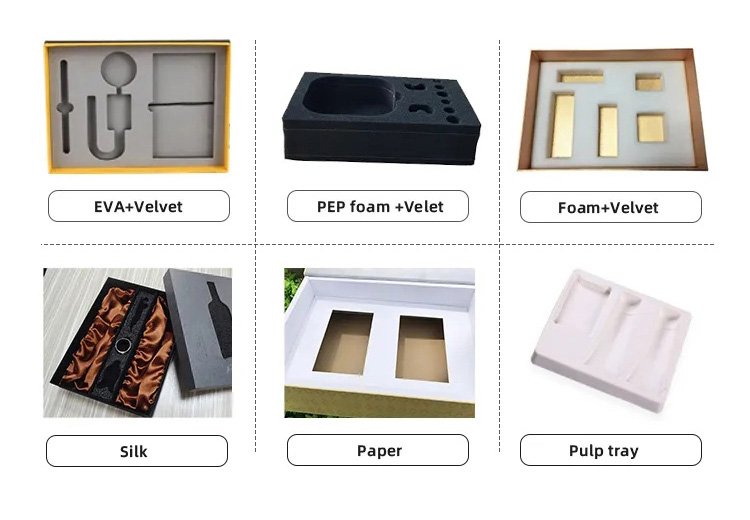

In addition to box shapes, interior linings play a crucial role in protecting your products and enhancing the unboxing experience. Prime Printings offers various lining options, such as foam inserts, silk linings, velvet linings, etc. These linings add a luxurious touch and ensure that your products are safely secured within the paper boxes.

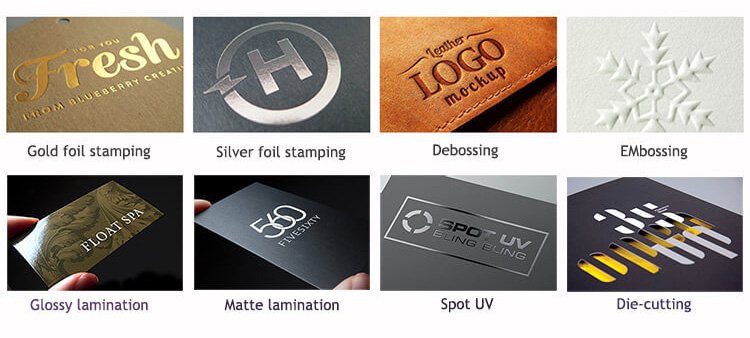

Finish Options

The finish of custom jewelry box packaging serves as the final touch that elevates its visual appeal, tactile experience, and overall perceived value. At Prime Printings, we offer a range of exquisite finishing options to enhance and customize jewelry boxes. Ensuring that each packaging solution reflects the brand's identity and resonates with its target audience.

Glossy/matte lamination

Glossy or matte lamination adds a protective and polished finish to custom jewelry box packaging. The choice between glossy and matte lamination depends on the desired look and feel of the jewelry box. With glossy lamination offering a reflective and vibrant surface, and matte lamination providing a subtle and elegant texture.

Foil stamping

Foil stamping is a luxurious finish option for custom jewelry box printing, adding metallic accents and embellishments to the box. Whether it's gold, silver, or other metallic colors, foil stamping creates a stunning visual impact and a touch of opulence to your custom printed jewelry box, making it a memorable and sophisticated packaging solution.

Spot UV

Spot UV is a technique that applies a glossy and raised coating to specific areas of the custom jewelry box. It creats contrast and highlighting certain elements of the design. This finish option adds a tactile and visual dimension to the jewelry packaging. Drawing attention to intricate details and adding a premium touch to the overall presentation.

Emboss

Embossing creates a raised impression on the surface of the custom jewelry box, adding texture and depth to the design. By elevating specific elements of the artwork or text, embossing enhances the tactile experience of the jewelry packaging. It creats a sense of luxury and craftsmanship that resonates with customers.

Deboss

In contrast to embossing, debossing creates a depressed impression on the surface of the custom jewelry box. It adds a subtle and sophisticated texture to the design. This finish option adds a tactile and visual interest to the jewelry packaging, conveying a sense of refinement and elegance.

Varnish

Varnish is a clear coating that can be applied to custom jewelry box packaging to enhance the overall appearance and protect the printed design. Whether it's a glossy or matte varnish, this finish option adds a layer of protection and sheen to the jewelry box. Ensuring the longevity and visual impact of the custom printed jewelry box.

Artwork Tips

When preparing the pre-press file for printing, it's essential to follow specific guidelines to ensure the successful production of your custom printed jewelry box. Here are the key steps to set up the jewelry box pre-press file for printing:

Design software: Use professional design software such as Adobe Illustrator or Adobe Photoshop to create the artwork for your custom jewelry box. Set the document to the correct dimensions and ensure that the design is aligned with the printing specifications provided by Prime Printings.

Bleed and safety zone: Extend the artwork beyond the trim line to create a bleed area, ensuring that the design extends to the edge of the custom jewelry box. Besides, keep essential elements such as text and logos within the safety zone to prevent any trimming issues during production.

Color mode: Set the color mode to CMYK for full-color jewelry box printing, ensuring that the artwork is accurately represented in the printing process. If you have specific Pantone colors, ensure that they are correctly specified in the artwork for precise color reproduction.

Image resolution: Use high-resolution images (at least 300 dpi) for any photographic elements or intricate details in the design to ensure sharp and clear printing on the custom jewelry box.

Die-cut and fold lines: If your custom jewelry box features unique shapes or structural elements, clearly indicate the die-cut lines and fold lines in your artwork files. Provide separate layers or guides for die-cut lines to indicate the outline of the box and any intricate patterns or shapes. Similarly, delineate fold lines to communicate where the box will be folded and assembled, ensuring that the design aligns seamlessly across different panels and surfaces.

File format: Save the artwork in the appropriate file format (e.g., PDF) with the correct settings for printing. Including the necessary color profiles and trim marks to indicate the final dimensions of the custom jewelry box.

At Prime Printings, we understand the importance of custom jewelry box packaging in elevating your brand and enhancing the presentation of your jewelry items. With our expertise in custom jewelry box printing, we are committed to delivering exceptional quality and craftsmanship to meet your specific requirements. Whether you're looking for custom jewelry box with logo, or other paper box printing, we offer a range of options to bring your vision to life. Contact us today to discuss your custom jewelry box printing needs and discover the possibilities for creating personalized and captivating jewelry packaging.