Contact Us

(888) 595-0219

Liberty Plaza 165 Broadway Lower Manhattan, 7th Floor, NY, 10006, USA

Cardboard Box

Custom Cardboard Box Printing Company

Custom Cardboard Box Printing Company

As a professional Prime printer in the printing industry with rich custom printing experience. We offer a wide range of options (from paper to finish options) to ensure that your custom cardboard boxes are not only visually appealing but also durable and functional.

- ☑ Competitive price

- ☑ A wide range of customized options

- ☑ Professional quality printing

- ☑ Truly customer-centric customer service

- ☑ Fast delivery

- ☑ Worldwide shipping

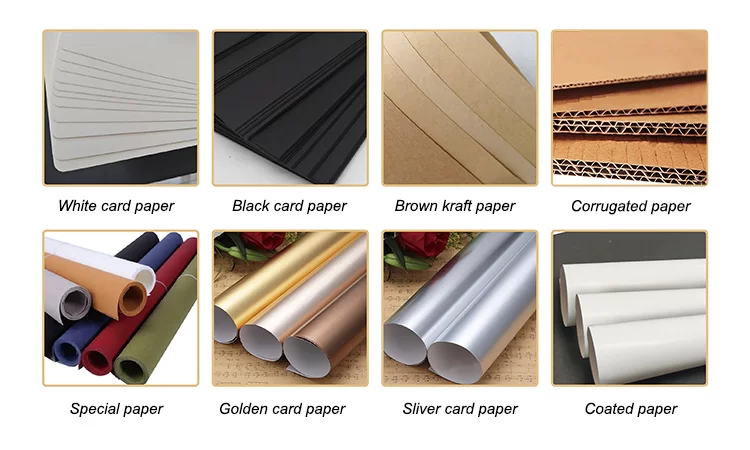

Materials

At Prime Printings, we understand that the material of your cardboard box is crucial in conveying the right impression for your brand. We offer a variety of materials to suit different needs, including C1S paper, C2S paper, corrugated paper, Kraft paper, and special paper. Each material has its own unique characteristics and strengths.

C1S paper

C1S paper, also known as coated one side paper, is a popular choice for custom cardboard box printing. It features a glossy, reflective surface on one side, making it ideal for vibrant and eye-catching designs. The coated side of the paper provides excellent ink adhesion, resulting in sharp and vivid printed images.

C2S paper

C2S paper, or coated two sides paper, is another versatile option for making custom cardboard box. This type of paper is coated on both sides, offering superior printability and a smooth finish. It is well-suited for intricate designs and detailed graphics. Making it a preferred choice for premium packaging solutions.

Corrugated paper

Corrugated paper is renowned for its strength and durability. Making it an excellent choice for cardboard box packaging printing. It consists of a fluted inner layer sandwiched between two outer layers, providing exceptional protection for the packaged contents. Additionally, corrugated paper can be customized to various thicknesses to meet specific packaging requirements.

Kraft paper

Kraft paper is a sustainable and eco-friendly option for custom cardboard gift and packaging box printing. It is known for its natural, rustic appearance and excellent tear resistance. With its earthy charm, Kraft paper is often chosen for eco-conscious brands looking to convey a message of environmental responsibility through their packaging.

Special paper

Apart from the standard options, Prime Printings also offers a range of special paper choices for cardboard box custom service. These include textured papers, metallic papers, and specialty finishes that add a unique touch to the packaging, making it stand out on the shelf.

When printing cardboard paper box, you need to consider the material that best aligns with your brand image and the intended use of the boxes. Whether you require sturdy corrugated cardboard boxes for shipping or elegant Kraft paper boxes for retail packaging. Our wide selection of materials ensures that you will find the perfect fit for your cardboard box printing needs.

- Kraft paper: 200gsm, 250gsm, 300gsm, 350gsm, 400gsm

- Coated one side Art Paper(C1S): 200gsm, 250gsm, 300gsm, 350gsm, 400gsm

- Coated two side Art Paper(C2S): 250gsm, 300gsm, 350gsm, 400gsm

- Specialty paper : 250gsm, 300gsm, 350gsm

- Back card paper: 200gsm, 250gsm, 300gsm, 350gsm, 400gsm

- Corrugated Paper: B.E.F.K3.K9 Flute

Printing Methods

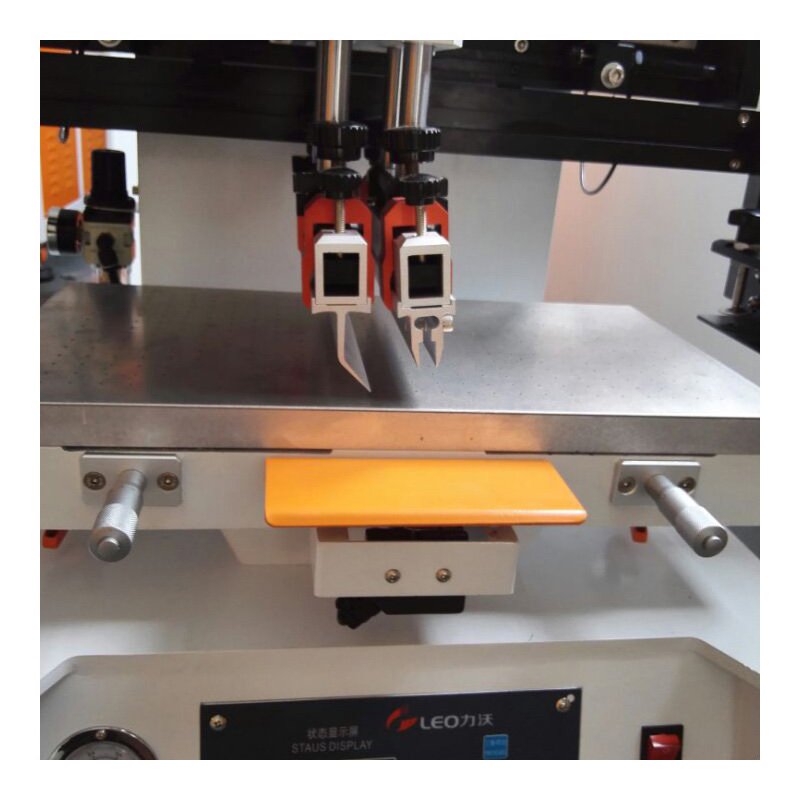

The printing method used for cardboard box printing services will affect the final look and quality of the boxes. At Prime Printings, we offer various printing methods, including CMYK offset printing, Pantone color offset printing, UV printing, and screen printing. Each method has its own advantages and is suitable for different design requirements.

CMYK offset printing

CMYK offset printing

CMYK offset printing is a widely used method for custom cardboard box printing services. Especially for designs that require full-color reproduction. This printing process involves the use of four primary ink colors – cyan, magenta, yellow, and black – to achieve a broad spectrum of hues and shades. It is ideal for intricate, multi-colored designs and photographic images.

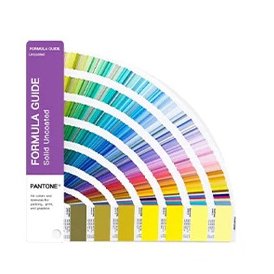

Pantone color printing

Pantone color printing

Pantone color printing is chosen for printing cardboard box when precise color matching is essential. The Pantone Matching System (PMS) allows for the selection of specific spot colors from a standardized color library, ensuring consistency across different print runs. This method is often preferred for branding elements that require exact color reproduction.

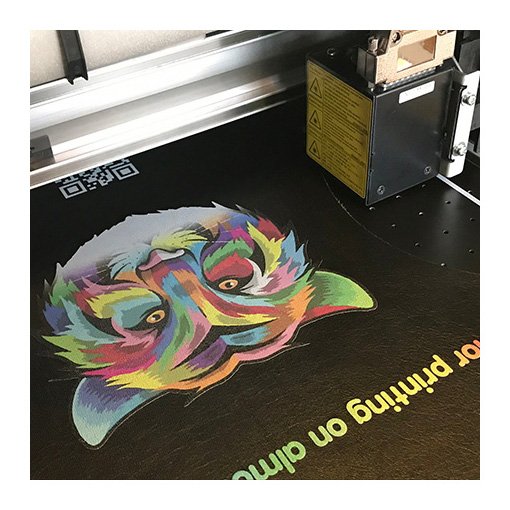

UV printing

UV printing

UV printing offers a high-gloss, premium finish for customized cardboard box printing. This method involves the use of ultraviolet light to cure inks instantly, resulting in vibrant colors and enhanced durability. UV printing is suitable for creating impactful visual effects. Such as raised textures or glossy highlights, that elevate the overall appeal of the packaging.

Screen printing

Screen printing

Screen printing is a versatile and cost-effective method for making custom cardboard box. It is well-suited for bold, solid colors and simple designs, making it a popular choice for large-scale productions. With its ability to apply thick layers of ink, screen printing can create eye-catching effects and textures that stand out on the packaging.

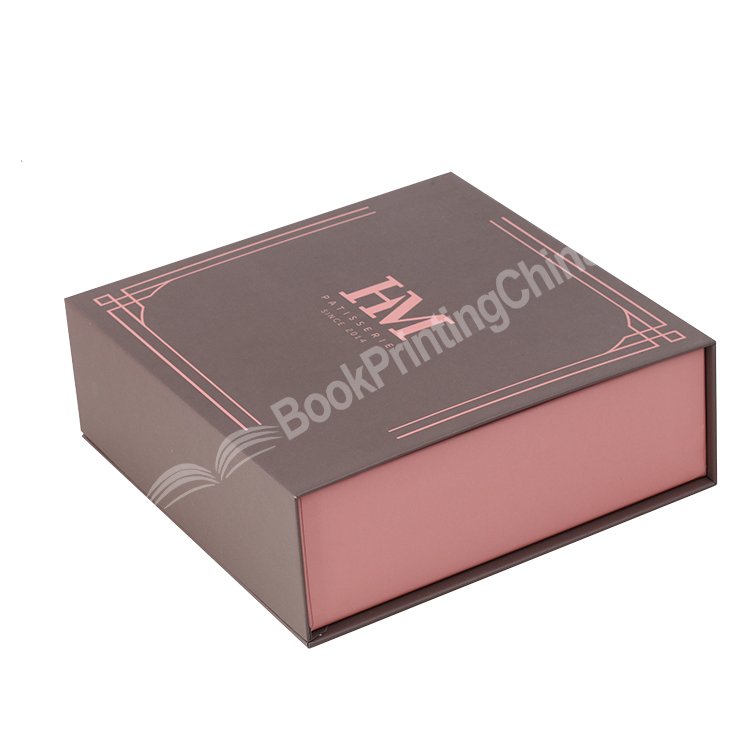

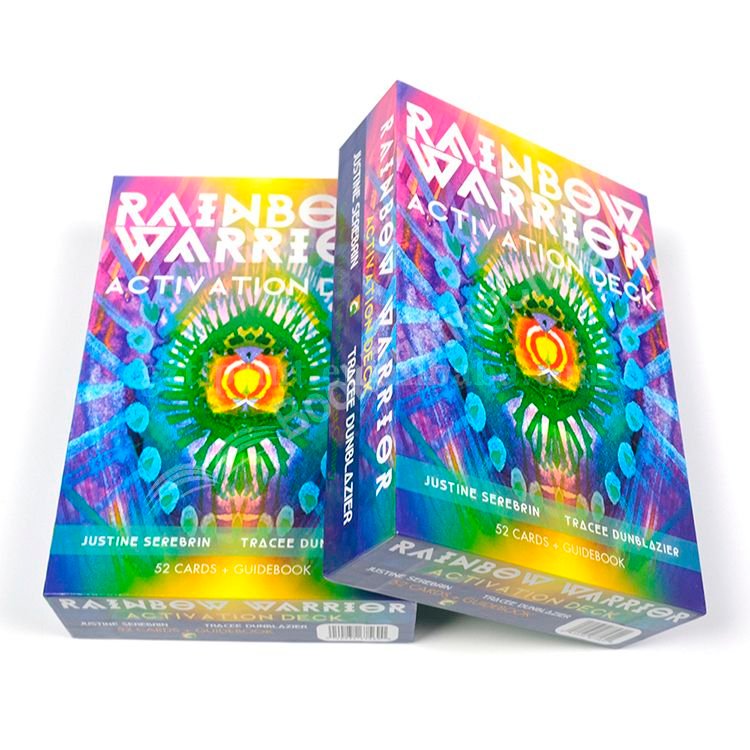

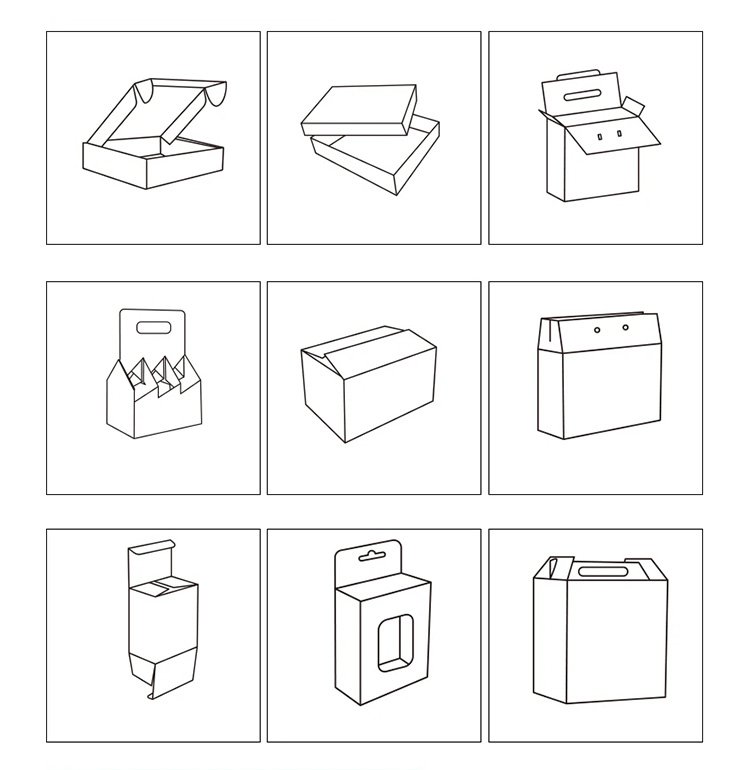

Box Styles and Lining Options

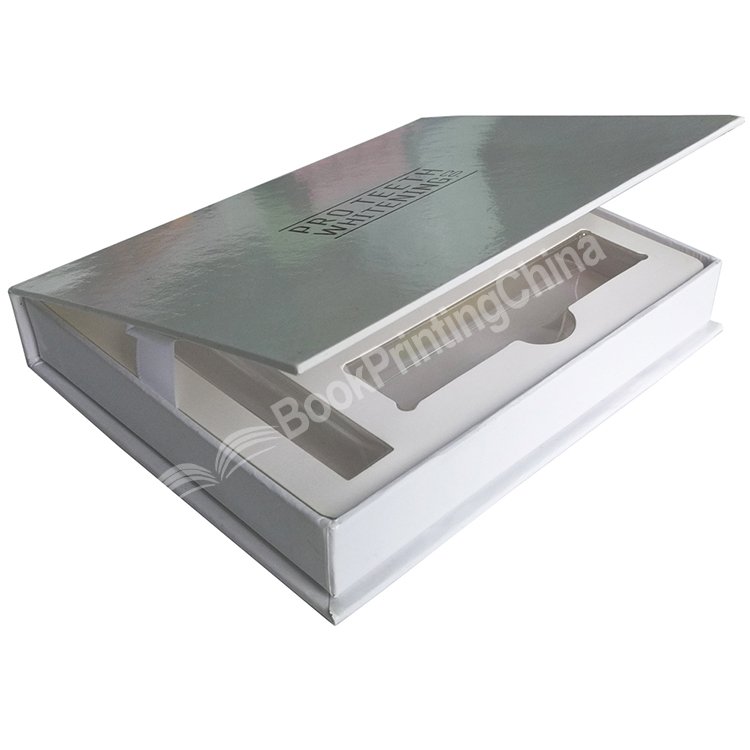

Prime Printings understands that different products require different box shapes and interior linings. We offer a wide range of options to cater to your specific needs. Whether you need a standard rectangular box, a round box, or a custom shape, we have the expertise to bring your vision to life. Our skilled team can create intricate die-cut designs, ensuring that your paper boxes are not only functional but also visually appealing.

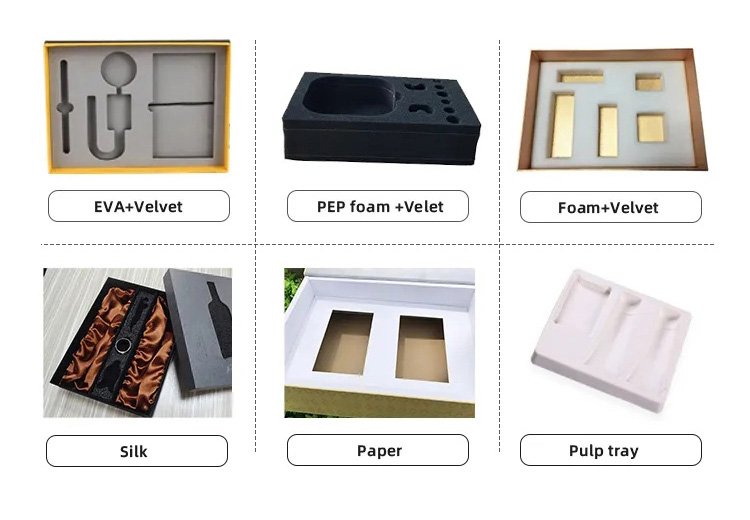

In addition to box shapes, interior linings play a crucial role in protecting your products and enhancing the unboxing experience. Prime Printings offers various lining options, such as foam inserts, silk linings, velvet linings, etc. These linings add a luxurious touch and ensure that your products are safely secured within the paper boxes.

Finish Options

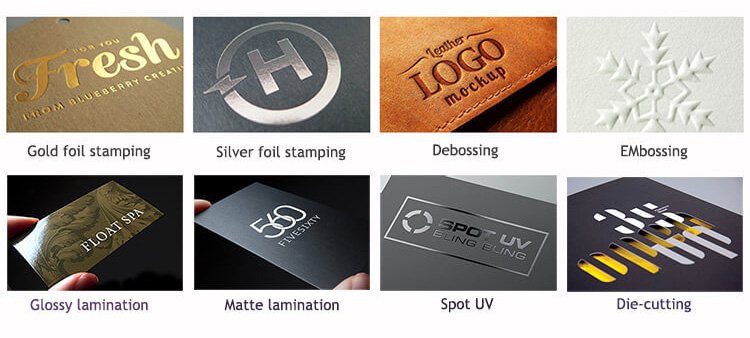

Except for the material and printing method, the finish options available at Prime Printings can add a touch of sophistication and refinement to your custom cardboard boxes. We offer a range of finish options, including glossy lamination, matte lamination, varnish, embossing, debossing, foil stamping, and spot UV. Each finish option enhances the visual and tactile appeal of your cardboard boxes in its own unique way.

Glossy/matte lamination

Glossy and matte lamination are popular finish options for custom cardboard box printing. Glossy lamination adds a reflective, shiny surface to the packaging, creating a luxurious and attention-grabbing effect. While matte lamination provides a subtle, velvety texture that exudes elegance and sophistication.

Varnish

Varnish is a transparent coating applied to printed cardboard boxes to enhance specific design elements or provide overall protection. It can be used to create glossy highlights, add texture, or impart a tactile sensation to the packaging. Varnish offers versatility in customizing the visual and tactile aspects of the printed design.

Embossing/debossing

Embossing and debossing are tactile finish options that add dimension and texture for cardboard box. Embossing creates raised, three-dimensional effects, while debossing creates recessed impressions. These techniques are used to accentuate logos, patterns, or text, adding a tactile and visual element that captures attention.

Foil stamping

Foil stamping is a sophisticated finish option that imparts a metallic or colored foil onto specific areas on cardboard box. It creates a striking contrast against the base material, adding a touch of opulence and elegance to the packaging. Foil stamping is often used for branding elements and decorative accents.

Spot UV

Spot UV is a modern and impactful finish option for custom cardboard box printing. It involves applying a glossy, raised coating to specific areas of the design, creating a contrast in texture and shine. Spot UV adds visual interest and depth to the packaging, making it visually striking and memorable.

Artwork Tips

Setting up artwork for cardboard box printing is a key step that directly influences the quality and accuracy of the final output. It requires attention to detail and adherence to specific guidelines to ensure seamless production.

Design software and templates: The first step in setting up a cardboard box pre-press file is to choose the appropriate design software and templates. At Prime Printings, we provide detailed templates and guidelines for various box styles and dimensions. To make sure that the design files are compatible with our printing processes.

Bleed and safety margins: When creating the pre-press file for your cardboard box, you need to incorporate bleed and safety margins to accommodate any variations in the cutting and folding processes. Bleed extends the design beyond the trim edge, preventing any white borders from appearing. While safety margins ensure that essential design elements are not compromised during production.

Color mode and resolution: Selecting the correct color mode and resolution to achieve accurate and vibrant printed results. The pre-press file should be set to CMYK color mode to ensure that the colors translate accurately from the digital design to the printed output. Additionally, the resolution of images and graphics should be set to a minimum of 300 dpi to maintain crisp and clear details.

File format and export settings: The pre-press file should be saved in the appropriate file format, such as PDF. With the necessary export settings to preserve the integrity of the design elements. It is important to outline fonts, embed images, and flatten transparencies. To ensure that the file is print-ready and free from any potential issues during production.

Proofing and approval process: Before sending the pre-press file to custom cardboard box manufacturer, you need to carefully proofing. This involves reviewing the design for accuracy, color consistency, and structural integrity to identify and address any potential issues before approvaling to the printing stage.

Prime Printings is a professional printing and packaging manufacturer over 25 years. We offers offers a wealth of possibilities for brands looking to create impactful packaging solutions. Whether you want custom cardboard boxes for packaging, retail displays, or promotional purposes. Our expertise and dedication to quality ensure that your cardboard boxes make a lasting impression.

If you're ready to elevate your brand with custom cardboard box printing. Contact us today to get free quote and explore the possibilities of premium printing solutions.